We are pleased to share with you a project executed by After Sales Department from J.Huesa for, Masiá Ciscar, a red fruits production leading company located in Huelva. Currently, this company is focused on the cultivation of genuine varieties of strawberries and is continuous growing.

Once the analytical parameter of raw water and client’s requirements are known, technical team from J. Huesa started to study and design a solution for a client’s trouble.

Water data and properties

Plant has been designed to treat a wastewater from warehouse and obtain a treated water which properties are similar to domestic water, aiming to accomplish with environmental parameters defined by current wastewater legislation.

The baseline data are as follows:

| CALCULATION BASIS | |

| Population (habeq) | 75 |

| Consumption (l/inhab day) | 150 |

| COD (g/ inhabeq day) | 90 |

| BOD5 (g/ inhabeqdía) | 60 |

| MES (g/ inhabeqday) | 90 |

| DESIGN FLOW RATES | |

| Daily flow (m3/day) | 75 |

| Average flow (L/h) | 150 |

| Peak flow (L/h) | 90 |

Adopted solution

Considering environmental requirements, main physical and chemicals properties of the raw water and legislation, technical team from J. Huesa decided to design a total oxidation compact wastewater treatment plant.

This plant includes the following sub-processes:

Pretreatment

Aiming to avoid wrong working and blockage of the feeding pump to wastewater plant, caused by solids presented in raw water, it has been installed a roughing screen in order to retain the coarsest solids (> 1 mm).

Detail of screen

Following, water is pumped to a vertical screw screen, which will be programmed according to the amount of solids in the water and solids will be separated thanks to the action of a worm screw.

Detail of the screw conveyor

Total oxidation compact treatment plant

System will be operated according to a sequential total oxidation with nutrient removal. This will be possible thanks to a biological treatment that will be carried out in a sludge biological reactor.

Plant is composed by a primary equalization tank before biological reactor that allows to retain fats and oils and main particles presented in raw water due to these could be cause problems in the proper work of the biological reactor, obtaining a worse degradation of the matter and, thus, a worse quality in clarified water produced.

Moreover, it has been installed a primary decanter which enable to laminate the flow, increasing the performance and maintenance cycles of equipment.

Detail of the sewage treatment plant during the installation process

Description of the treatment applied:

- Decanter – Homogenizer: Settling and digestion of the particles and organic matter presented in raw water will be carried out in a decanter-homogenizer which allows to retain a great part of drifting particles avoiding that reach the biological reactor.

- Reactor – clarifier: In order to carry out the biological treatment will be installed a reactor-clarifier which will make 4 task a day (4 cycles of six hours each). Following will describe each task:

-

- Filling: Reception of a determined volume of water from the primary clarifier through action of pumps.

- Reaction: at this stage, aerobic phases (which allow the biochemical decomposition of organic matter and nitrification) and anoxic phases (that produce the elimination of nutrients) are combined.

- Settling: In this phase, the sludge settling will be carried out in the absence of agitation and aeration. In this stage will be observed three different phases: supernatant, clarified (in the intermediate part) and sludges (at the lower part).

- Emptying: the treated water is pumped on the outlet manhole

A sampling pit has been installed at the outlet of the treatment plant for the control and monitoring of the effluent. Good sampling is essential for the proper control of the performance of the equipment.

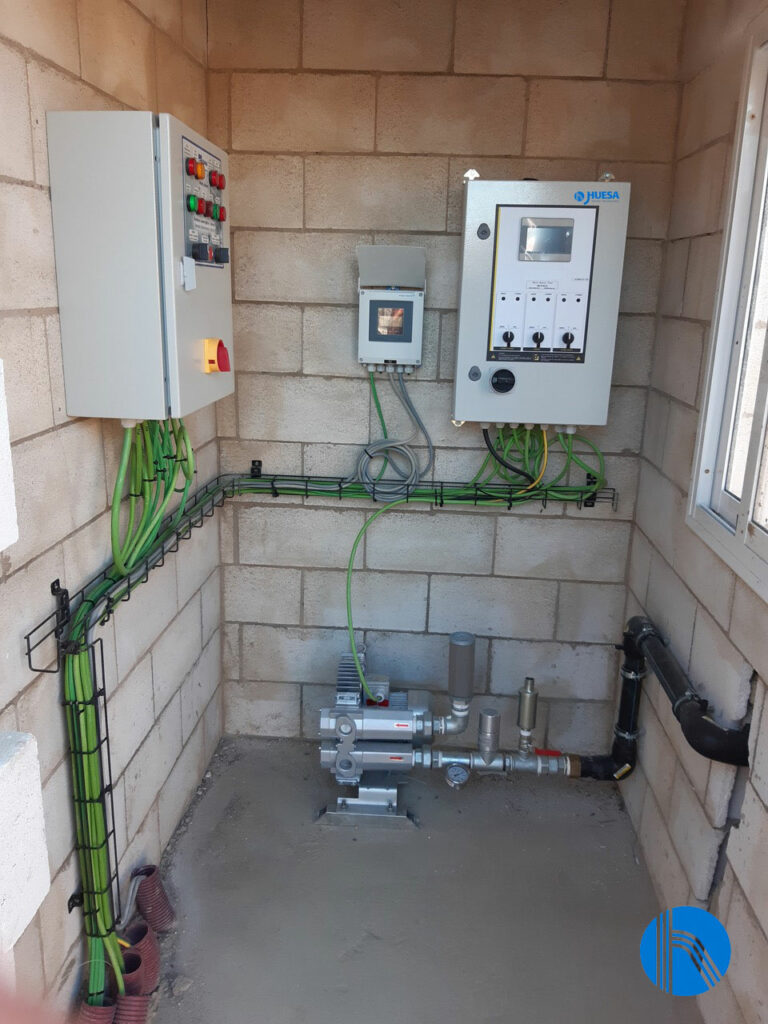

Instrumentation and control

Plant is equipped with instrumentation and control elements which are installed in an electrical protection panel that controls the operation of the equipment without needs on-site assistance.

Detail of electrical panel