Unlike anaerobic biological treatment, the strain of microorganisms used for the metabolization of organic matter requires oxygen, which acts as a final electron acceptor, resulting in higher purification efficiency, an energy requirement in order to supply oxygen, and high sludge generation caused by the growth of microorganisms. The system used to clear the microorganisms from the purified water classifies the different types of aerobic treatment technologies:

Technologies

AEROBIC BIOLOGICAL TREATMENT

- Conventional biological treatment through decantation: The mixed liquor is clarified in a decanter.

- Conventional biological treatment by flotation: the clarification of the mixed liquor is carried out in a DAF float tank.

- SBR (Sequential Biological Reactor): this technology integrates the biological reactor and decanter in the same tank, and the system operates using treatment batches developed over timed stages, with one of the process stages being mixed liquor clarification. This reduces the space occupied by the plant (compared to the conventional system) and increases the flexibility of the aeration-anoxia processes required for nitrogen removal.

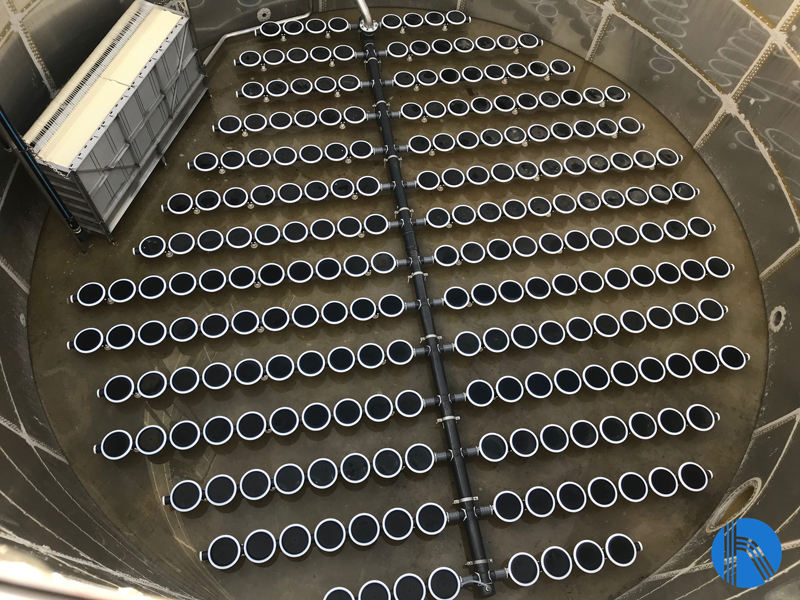

- MBR (Membrane Biological Reactor): in this case, the process of separating the biomass from the effluent does not take place through decantation, but rather through filtration through ultrafiltration membranes. In addition to reducing the space occupied by the facility, because it allows it to work using high concentrations of mixed liquor, it produces a high quality effluent (free of bacteria and viruses) and pretreated for reverse osmosis refining treatments. Depending on the placement of the ultrafiltration membranes, we distinguish between external membranes (membranes outside of the mixed liquor) and submerged membranes (membranes inside the mixed liquor).

- MBBR (Moving Beds Bio Reactor): In this type of reactor, the culture is attached to a filler that is suspended in the mixed liquor, so that no clarification is required, except for a refining decantation for those floccules that become detached from the filler. This solution reduces the volume of the reactor compared to conventional solutions.

- Bacterial beds: the culture is attached to an immobile surface so no final clarification is required, since the culture is fixed to the filler. When the culture is attached to a rotating surface, those are called biodiscs. This application is used in small urban and industrial wastewater treatments because of its lower energy impact.

APPLICATIONS

- Industrial wastewater with biodegradable contamination

- Urban wastewater