Reverse osmosis is a membrane technology that removes salinity from water.

It is based on a process of diffusion through a semi-permeable membrane that facilitates the passage of dissolved gases and molecules without electrostatic charge of low molecular weight.

It is the system suitable for the production of pure water with a low salt content, free of viruses and chemical contaminants.

Osmosis membranes are used, the configuration of which varies according to the nature of the water to be treated.

Types of reverse osmosis according to membrane configuration:

Technologies

REVERSE OSMOSIS

- Spiral membranes

- Disc membranes

- Vibrating membranes

APPLICATIONS

The main uses of this technology are:

- Production of pure water in the biggest production sectors: chemical, food, energy, electronics, etc

- Treatment of saline effluents in which the removal of conductivity is desired

- For seawater desalination

- It enables the reduction of water consumption through regeneration and reuse.

ADVANTAGES

Some of the advantages of this treatment system are:

- Environmentally friendly systems

- Require a minimum amount of energy

- Occupy less space than other water treatment systems

- Fully automated

OPERATION

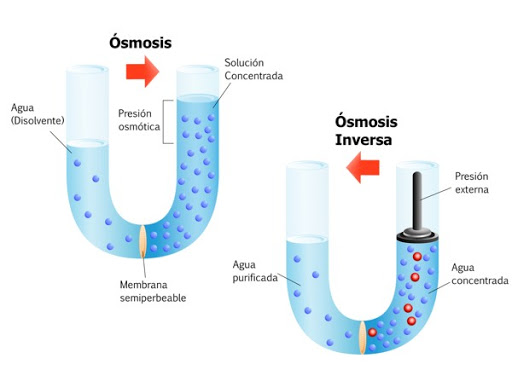

Osmosis is a phenomenon in which molecules move across through a porous semi-permeable membrane from a region of lower concentration to a region of higher concentration, the objective of the membrane being to equalize the concentrations on both sides.

This influx of particles into the zone of lower concentration is known as osmotic pressure.

In reverse osmosis, a pressure higher than the osmotic pressure is used, achieving the opposite effect.

The higher the applied pressure, the higher the proportional increase of the permeate flow rate.

Factors that effect the membrane filtration process:

- Quality of input water.

- Plant operating parameters (pressure and degree of conversion).

- Polarization of the concentration.

All this can lead to biofouling (contamination of the membrane), the buildup of salts in the membrane, or even degradation of the membrane.

To stop these things from happening, it is essential to apply the proper pretreatment. Typical pretreatment may include:

- Filtration

- Ultrafiltration

- Dosing system (antiscalant-repressor)

- 5-micron cartridge filter

To ensure that the osmosis works correctly, it is essential to carry out the proper pretreatment, as well as preventive and corrective maintenance of the operation.

The lifespan of reverse osmosis equipment depends to a large extent on proper pretreatment, preventive plant maintenance, and O&M.

J. Huesa Water Technology guarantees its customers the maximum duration of osmosis facilities through the application of correct pretreatment and preventive maintenance of the facility.

Some of the advantages acquired are:

- Increase in the half-life of membranes

- Improvement in water production and quality

- Reduction of losses due to downtime

- Reduction in O&M costs