We share with you a new success story. We supplied a containerized plant for a leading chemical industrial cleaning company. Our client, a multinational company, needed to treat the effluent from industrial chemical cleaning in a factory in Taiwan.

After studying the needs of our client, the technical team of J. Huesa opted for the design of pre-treatment by filtration and reverse osmosis treatment with a capacity of 20 m3/hour

Background and design data

Design capacity

The plant has been designed to guarantee the treatment of 20 m3/h of raw water, obtaining a permeate flow of 8 m3/h and a reject flow of 12 m3/h.

| Flow rate to ring filter | 20,00 m3/h |

| Flow rate to reverse osmosis | 20,00 m3/h |

| Reverse osmosis permeate flow rate | 8,00 m3/h |

| Reject flow rate reverse osmosis | 12 m3/h |

| Plant conversion | 40% |

Treated water requirements

The equipment supplied consists of a series of filtration equipment with the aim of removing the particles present in the water until it reaches a suitable micron size for it to be sent to the reverse osmosis process, in which the final permeate water of the treatment process is obtained.

| pH | 4,03 |

| Conductivity | 20.200 µS/cm |

| Redox | 15,90 mV |

| DO | 0,65 mg/L |

| TDS | 12.930 mg/L |

| Temperature | 17,30 ºC |

| COD | 22.980 mg/L |

| SS | 8,9 mg/L |

| Turbidity | 2,56 mg/L |

Table 1. Raw water characteristics

Adopted solution

After studying the starting conditions and the general objectives of the project, J. Huesa’s technical team has opted for the design, manufacture and supply of a containerized water treatment plant comprising the following treatment train:

- Pretreatment

- Reverse Osmosis

- Flushing and CIP System

Pretreatment

The water enters the plant directly driven by a submersible pump, inserted in the bottom of the basin provided by the operator.

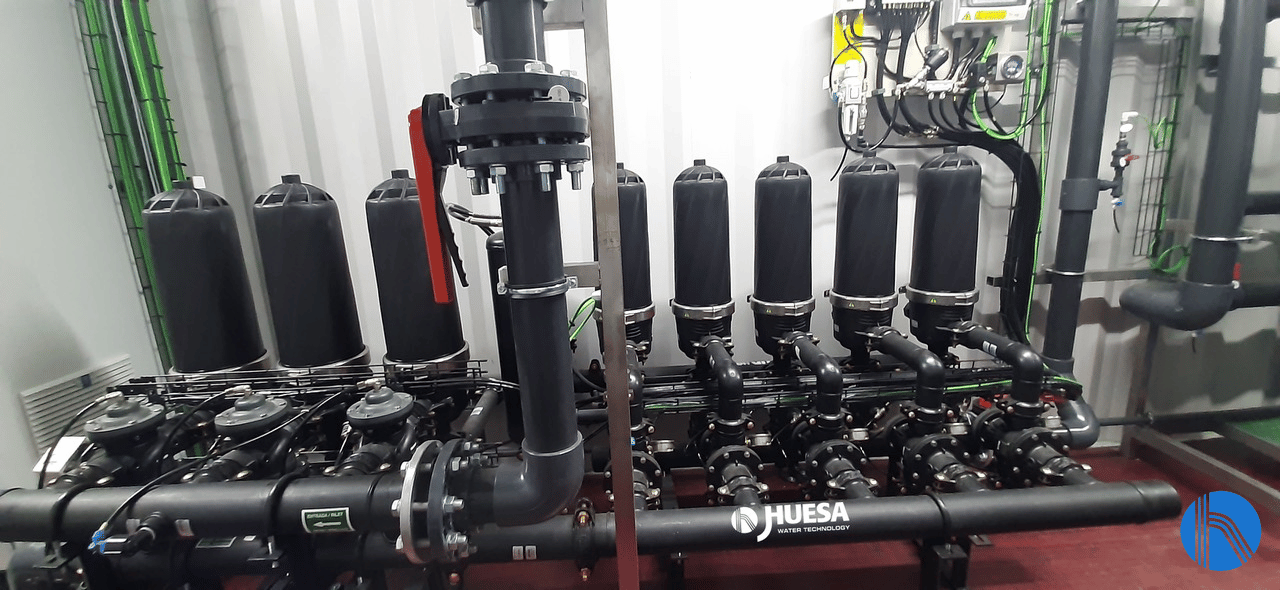

In an initial pre-treatment stage to facilitate the elimination of solids in the filtration stage, the water enters a battery of ring filters, equipped with a filtration stage, the water enters a battery of ring filters, equipped with a controller and automatic cleaning, with one stage of 3 bells with a filtration micronage of 100 microns and another of 5 bells with 10 microns.

The automatic cleaning process performs a backwashing sequence of the filtering hoods one by one, so that the production process can continue as the rest of the hoods are filtering at the same time.

Picture 1. Ring filtration system

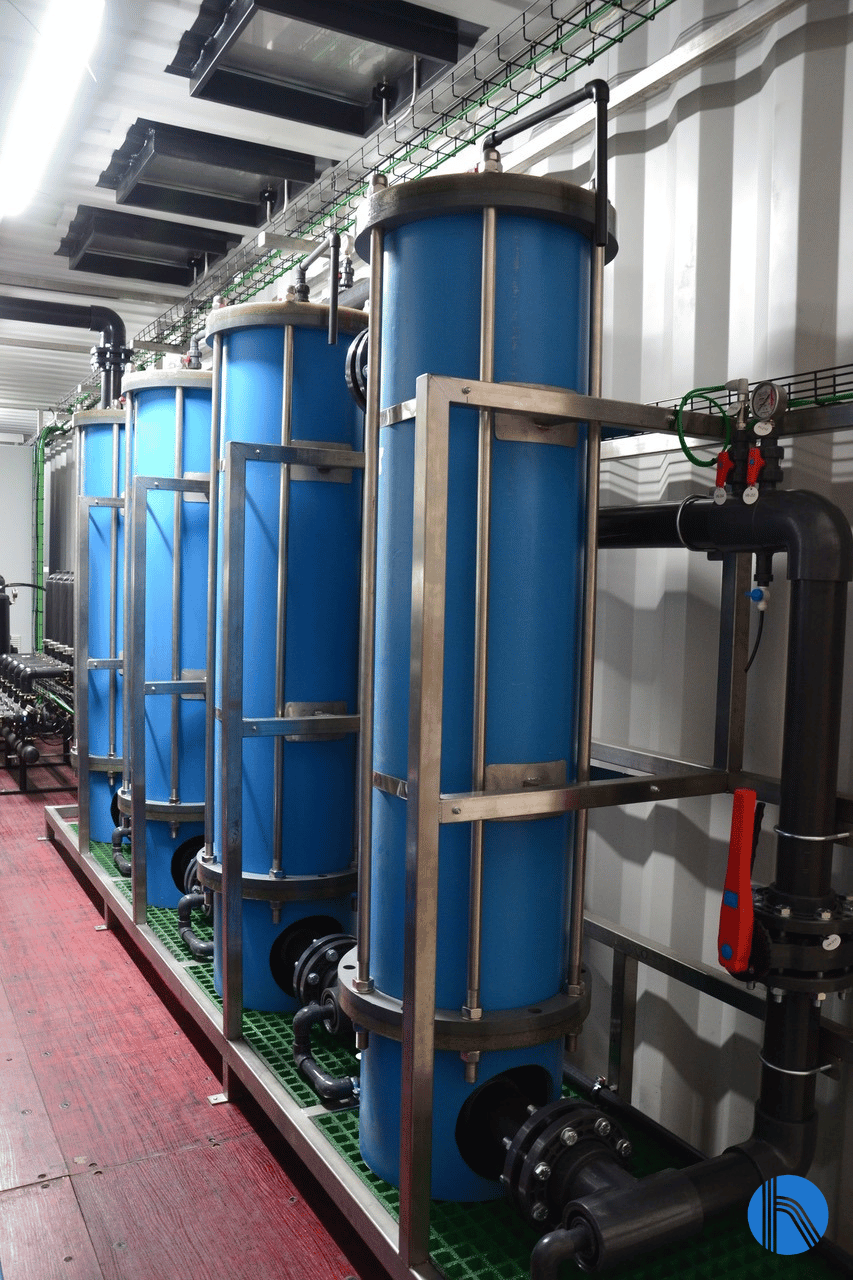

The water then passes through a system of cartridge filters, consisting of a PVC casing that houses replaceable cartridges with a specific filtration micron rating, so that the water is filtered through them.

On this occasion, we have opted for a model of 20 cartridges 40 inches long, both for cartridges with a nominal filtration degree of 5 microns and 1 micron; 2 filtration lines have been arranged, in order to have the possibility of working in a series or parallel configuration, so that the design allows “by-passing” the first or second line when it becomes saturated, making it possible to replace it while the plant is in operation.

When filter saturation occurs, this will be detected by the pressure transmitters provided for this purpose which will give an alarm indicating the need to replace the cartridges. When line 1 is saturated, the flow is redirected to the second line and the first line is disabled, so that we can carry out maintenance on the first line while operating with the second line.

Picture 2. Cartridge filtration system

Reverse Osmosis

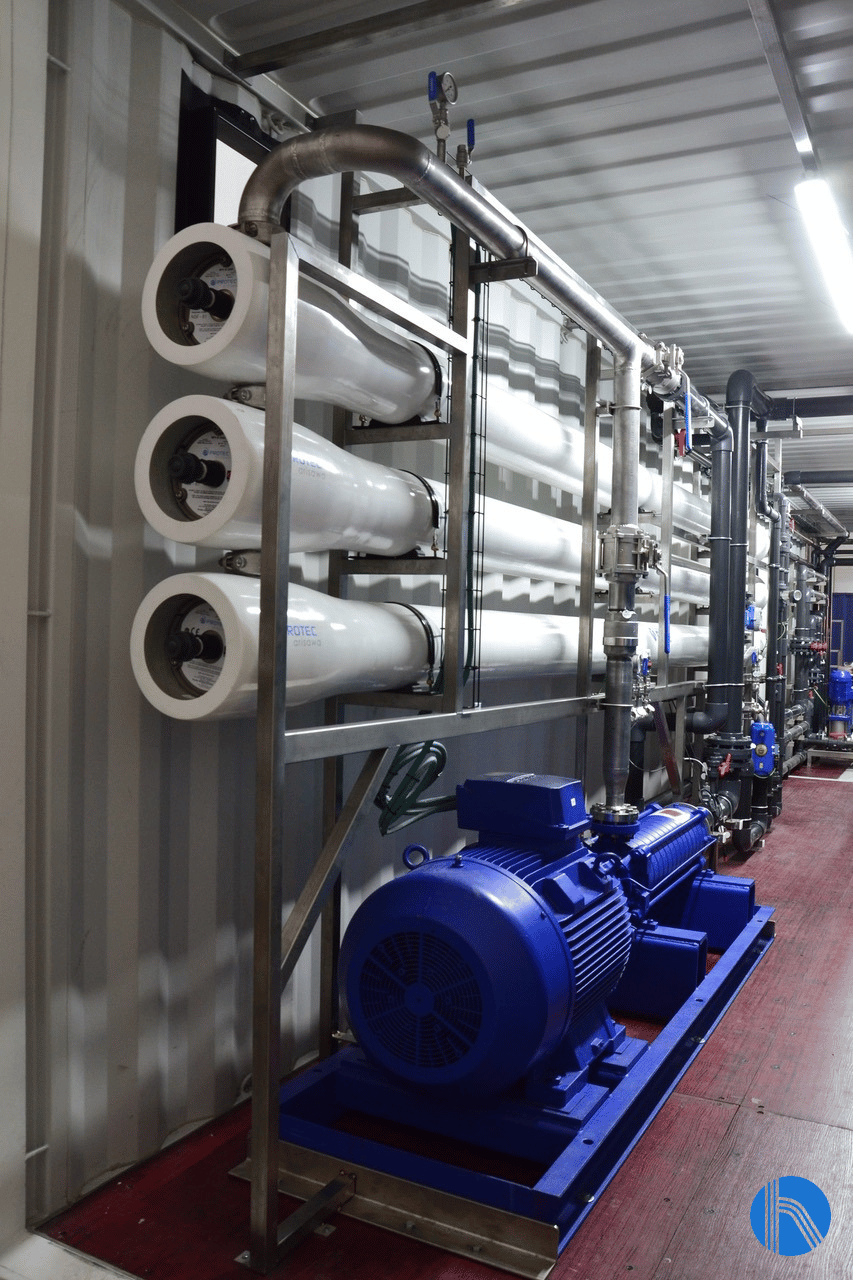

Once the water has been prepared, it is pumped by means of a vertical centrifugal pump, “in line”, in stainless steel AISI 316 with a capacity of 20 m3/h.

The reverse osmosis system is configured in a single stage, consisting of three pressure tubes each containing 5 membranes, achieving a conversion rate of around 40%.

The membranes are of spiral configuration, made of polyamide and special for brackish water up to 8000 ppm and with the characteristic of working at low pressure.

Picture 3. Reverse Osmosis System

Flushing and CIP system

All membrane plants become fouled over time, depending to a greater or lesser extent on the pre-treatment installed, requiring one to two chemical cleanings per year. The reverse osmosis plant includes a membrane washing system consisting of a reagent preparation tank, stainless steel recirculation pump and stainless-steel stage isolation and recirculation valves.

The filling of this tank is automatic thanks to a float valve connected to the same osmosis water line.

Instrumentation and control

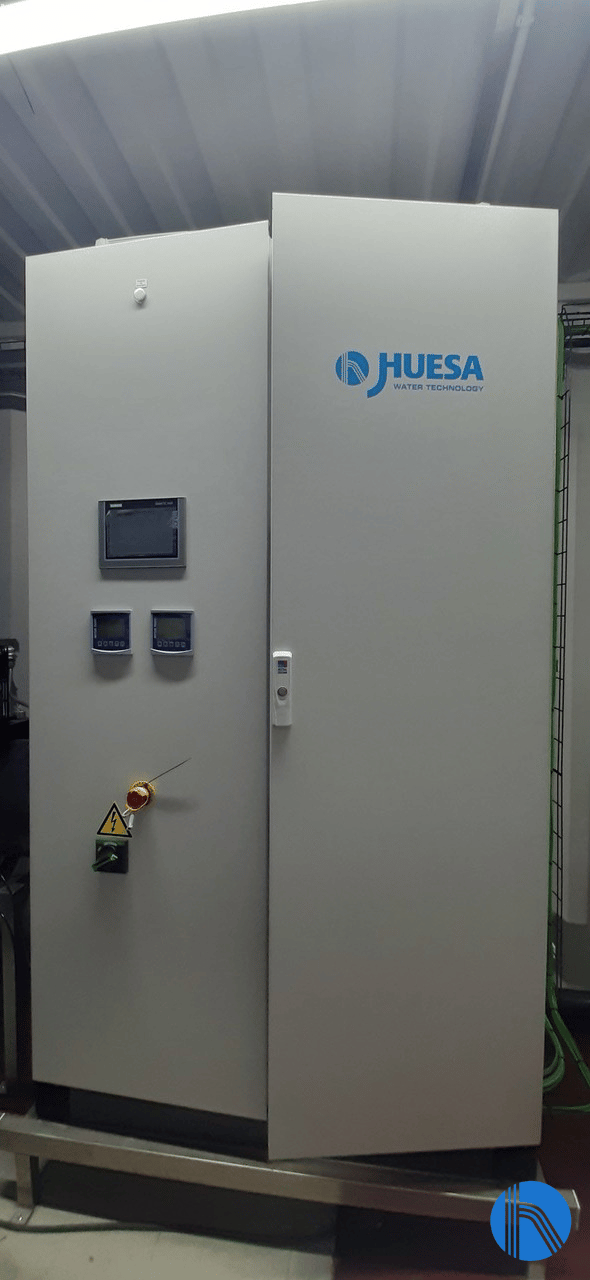

The reverse osmosis plant is equipped with instrumentation and control elements (automatic valves, pressure switches, pressure transmitters, flow meters, conductivity and Redox, etc.) which are centralized in an electrical panel located in the container.

The panel also includes a programmable logic controller and a touch screen for the operation and configuration of the plant. J. Huesa’s Instrumentation and Control team has designed the control panel so that it can be integrated in the client’s SCADA system, allowing a customized programming of all the operating parameters, as well as external connections of levels, alarms, pre-treatment, among others, through different I/O modules.

Picture 4. Electrical panel view