Water is widely used in the food industry; on this occasion we are going to analyze water contamination by chlorates and perchlorates, focusing on their origin, effects on the population and possible ways of elimination, bearing in mind that one of the keys to successful treatment is the selection of the most appropriate technologies for their elimination.

What are chlorates and perchlorates?

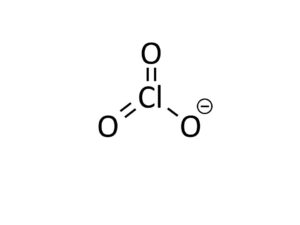

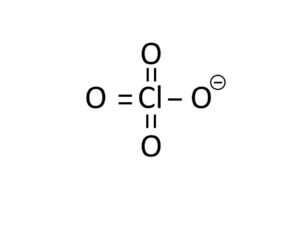

Both substances are odorless, colorless, inorganic anions that are very stable at room temperature. Chlorate originates from chlorine salts derived from chloric acid, while perchlorate originates from perchloric acid salts.

However, while the origin of chlorate is associated with the use of phytosanitary products, perchlorate, in general, comes from the degradation of hypochlorite (drinking water disinfectant) or fertilisers, as well as in the production of compounds for industry.

In general, irrigation water, soil, hypochlorite degradation and fertilizers are considered as possible sources of perchlorate contamination in food.

For their part, plant protection products are responsible for chlorate contamination in food, so their presence in food is regulated by legislation on residues of plant protection products. Its use as a plant protection product has been banned in the EU since 2008.

Formulas of chlorate (ClO3-) and perchlorate (ClO4-)

Risks to the population

EFSA, the European Food Safety Authority, is the European body responsible for providing independent scientific advice on food-related risks. It advises on existing and emerging risks and its opinions are implemented in European legislation and policies, contributing to the protection of consumers from risks in the food chain.

In the case of perchlorates, EFSA states that their absorption is harmful to human health, as it causes hormonal disturbances by influencing the normal functioning of the thyroid gland, leading to chronic diseases such as hyperthyroidism.

A double distinction should be made in the type of exposure to perchlorate:

- Chronic (prolonged over time);

- Or acute (occasional, but high concentration).

On the other hand, the population should be classified in terms of its vulnerability to such exposure as follows:

- Vulnerable (foetuses, neonates and population with genetic predisposition to thyroid diseases),

- And non-vulnerable (healthy adult population).

In the last decade, many studies have been carried out in this regard at the request of various EU member states, which is why Commission Regulation 2020/685 of 20 May 2020 amending Regulation (EC) 1881/2006 as regards the maximum content of perchlorate in certain foodstuffs came into being in 2020.

This Regulation establishes, among other things:

- The maximum perchlorate content both in foodstuffs with a significant perchlorate content and which contribute significantly to human exposure, and in foodstuffs relevant to the potential exposure of vulnerable groups of the population, such as infants and young children. Food businesses need to adapt to the new requirements.

- Recommendation to Member States to collect additional data on the presence of perchlorate in food in Europe, especially for vegetables, infant formulae, milk and milk products, in order to further reduce uncertainty in risk assessment.

| Foodstuffs | Maximum Level (mg/kg) |

| Fruits and vegetables, except:

– Cucurbitaceae and kale – Leafy vegetables and herbs |

0,05

0,10 0,50 |

| Té (Camelliasinensis), dried herbal and dried fruit infussions | 0,75 |

| Infant formulae, follow-on formulae and foods for special medical purposes intended for infants and young children, and infant formulae for young children.

Infant foods Processed cereal- based food |

0,01

0,02 0,01 |

Table extracted from the Annex of Regulation 2020/685

Similary, chlorates affect the functioning of the thyroid, which is why their maximum concentration is included in the legislation applicable to plant protection products, governed by the MRL (Maximum Residue Limit), which is the maximum concentration of a pesticide residue in food or feed that is legally tolerated if the application of the plant protection product is carried out correctly.

In 2020, Commission Regulation 2020/749 of 4 June 2020 amending Annex III of Regulation No 396/2005 of the European Parliament and of the Council as regards maximum residue levels for chlorate in certain commodities is enacted.

Until that date, no specific MRLs had been set for chlorate, and since it was not included in Annex IV of Regulation 396/2005, the default MRL of that Regulation (0.01 mg/kg) had applied.

Studies carried out by EFSA during the period 2014 – 2018 showed that the MRL for chlorates in food and drinking water frequently exceeded the 0.01 figure. Since chlorate is also formed as a by-product of disinfectants used in food processing, it was necessary to strike a balance between food safety and human health safety.

This Regulation sets temporary maximum limits in food, and in the specific case of chlorates from the use of chlorine-based compounds for food processing and drinking water disinfection, the limits should be set as low as possible (ALARA principle), while applying good manufacturing practices. The full list of products of plant and animal origin to which MRLs apply can be found in Annex I of Regulation 2020/749.

This approach ensures that, as far as possible, food business operators apply measures to prevent and reduce chlorate levels in food to protect public health, but also considers the need to ensure the microbiological safety of food

In addition, these MRLs will be reviewed by 8 June 2025 at the latest, depending on the evolution of the situation about hygiene, drinking water or developments in this respect.

How to eliminate the presence of chlorates and perchlorates in water

According to what has been explained so far, we can conclude that one of the ways to minimize the content of chlorates and perchlorates in food is to properly treat the water used in the different processes in which their use can lead to the appearance of these substances in food, such as irrigation water, water used in food transformation processes and even water purification.

At J. Huesa we have always insisted on the importance of the correct management of the integral water cycle, and as a fundamental part of this management, the use of the best technologies available in each specific case. Today we are going to focus on the treatment of water contaminated by chlorates and perchlorates.

Most conventional physical-chemical water treatments are not adequate for the removal of these ions, so the alternatives available to remove chlorates and perchlorates from water specifically require additional treatments to treat the concentrate that is generated.

Some of the technologies that can be applied for their removal are listed below:

Ion Exchange

Ion exchange technology is one of the most widely used methods to remove perchlorate contamination as a water purification application. Ion exchange resins are commercially available to remove perchlorate anion from aqueous waste streams.

Since the brine resulting from the use of this technology is high in perchlorate and total dissolved solids, further treatment is required for its removal; therefore, the ion exchange capacity for perchlorate is significantly reduced when treating waters with high levels of total dissolved solids and especially with waters with high levels of sulphates (each negatively charged double sulphate ion will replace two chloride ions). In these cases, more frequent regeneration of the resin bed is required and may not be cost-effective.

Since perchlorate has similar ion exchange properties to nitrate, nitrate selective resins that were developed to preferentially exchange nitrates rather than sulphates can be used to remove perchlorate by preventing sulphates from displacing or « dumping » nitrate or perchlorate when the bed reaches saturation.

Skid of Ion Exchange

Bifunctional ion exchange resins selective to perchlorate are available on the market, resulting in high selectivity and good exchange kinetics, favoring its removal from water; however, these types of resins are expensive, so they are not widely used.

Reverse Osmosis

Membrane technology used for the removal of chlorates and perchlorates from mains water for use in the food industry, among others, and which guarantees compliance with existing regulations. This technology ensures the total absence of salts in the permeate.

For the use of this technology to be effective, it is necessary to avoid problems of fouling or biofouling of the reverse osmosis membranes, for which a correct pretreatment of the water treatment plant is essential. Typical pre-treatment may include:

- Filtration

- Ultrafiltration

- Dosing system (antiscalant-reducer)

- 5-micron cartridge filte

Another important factor that plays an important role in the lifetime of this equipment is the O&M of the installation, as well as proper preventive maintenance.

Disinfection by physical means

To guarantee water quality in the sectors we are concerned with, it is necessary to resort to physical means of disinfection, the most common being ultraviolet radiation, and disinfection systems with ozone and oxygen peroxide as a refining treatment for the permeate obtained.

Skid disinfection with ozone

Conclusions

In view of the above, we can conclude:

- That we are facing a sector with a high demand for water quality, due to its repercussions on public health.

- That one way of guaranteeing success in water treatment is to know how the industry works and the legislation that applies to it, to approach water treatment with the technology or set of technologies that guarantee the requirements demanded by the legislation and operating costs that can be assumed by the industry.

- Good communication between the client and engineering is the basis for success, together with the application of pilots and R&D&I.