On this occasion we share with you an example of a turnkey project for a leading national company in the manufacture of torreznos and chorizo sausage that has recently moved its production centre and required the design and manufacture of an industrial wastewater treatment plant that would gradually adapt to the operation of the new factory.

After studying the needs of our client, J. Huesa’s technical team opted for the design and manufacture of a customized WWTP to be executed in phases, consisting of a system of roughing, screening plus pre-treatment by flotation and SBR biological treatment with a capacity of 30 m3/day, to be executed in two phases:

Phase I: Pretreatment and homogenization of the effluent

Phase II: Biological treatment by SBR

Background and design data

In line with the needs of our client, this first stage of the project has culminated in the installation and commissioning of the pretreatment and homogenization of the effluent, in accordance with the needs of the end client.

Design capacity

| Input flow | 30 m3/day |

| Working hours industry | 8 h/day |

| Working hours WWTP | 24 h/day |

| Peak Flow | 15 m3/h |

Treated water requirements

| Conductivity | 30 µs/ cm2 |

| pH | 6-9,5 |

| DQO | 1.100 mg/l |

| DBO | 400 mg/l |

| Oil and Fats | 100 mg/l |

| SS | 500 mg/l |

| Total Phosphorus | 5 mg/l |

| Total Nitrogen | 43 mg/l |

Adopted solution

Pretreatment: screening and degrasing

The discharge, due to its sector, shows an excess of oils and fats that may not be digested by the biological reactor, and may even affect its decantability.

Considering, moreover, that these substances can accumulate in the homogenization pond, the water is accumulated in a civil construction raw water reception well with a capacity of 25 m3.

Prior to degreasing, a stainless-steel roughing basket with a 20 mm clearance has been installed, in which solids with a larger diameter are retained. This will improve the biological reactor by eliminating large, non-dissolved organic matter, which is very slow to biodegrade.

From this well, the water is pumped to a stainless-steel surface rotary screen with a treatment capacity of 15 m3/h. The effluent enters the stainless-steel screen with a treatment capacity of 15 m3/h. The effluent enters the rotary screen with a clearance of 1 mm through the inlet pipe and is evenly distributed over the entire length of the filter cylinder which rotates at low speed.

The solid particles are retained on the surface of the screen and are conveyed to the scraper, which is responsible for separating them and depositing them on an inclined tray for them to fall by gravity to the collection container for waste management. The liquid that passes through the slits in the filtering cylinder is led to the outlet located at the back of the body.

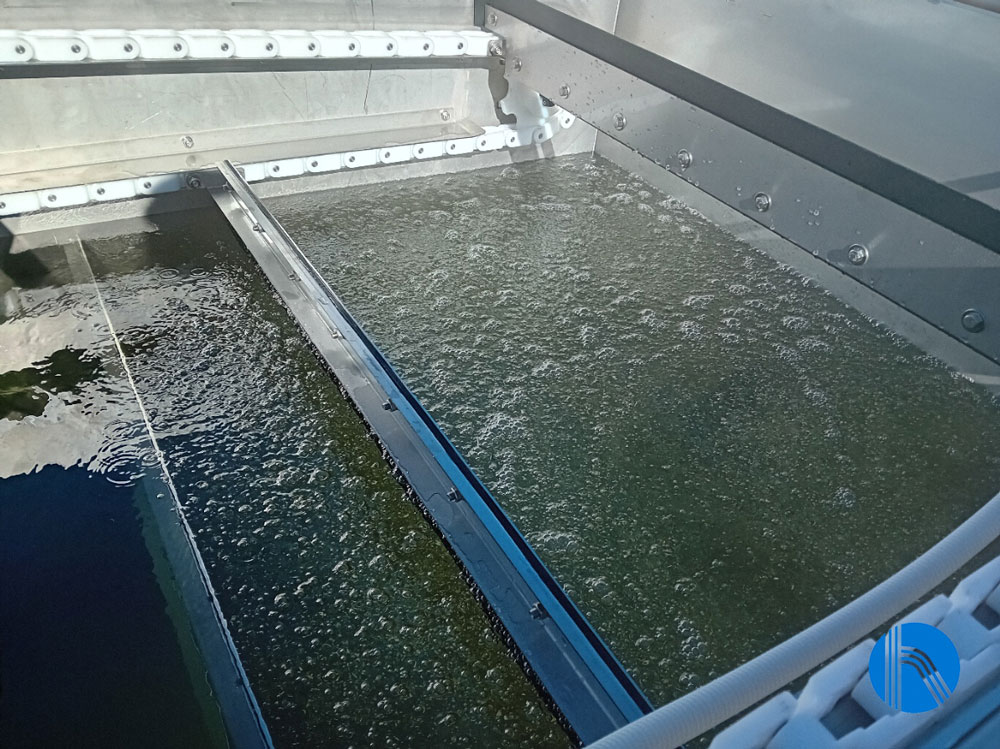

Picture 1. Detail of microbubble production from degreasing

Picture 1. Detail of microbubble production from degreasing

The effluent thus treated then passes into the CAF type degreaser, which has a treatment capacity of 15 m3/h and a retention time of 15 minutes. Specifically, it enters by gravity into the flotation chamber where the microbubble-generating turbine is housed.

Suspended solids and fats adhere to the microbubbles and are lifted to the surface where a surface sweeping system separates them from the water and transports them to the solids outlet.

The heavier solids that do not float settle on the inclined bottoms and are periodically removed by purge valves.

The treated water passes through a siphonic system and exits at the top of the equipment through an adjustable weir that allows the best internal working height to be chosen, adapting to the type of solid and the quantity to be separated.

Homogenization

The SBR system develops over time and therefore requires the accumulation of discharges to be able to manage the reactor feed in a controlled manner. On the other hand, a homogeneity of loads favors the behavior of the treatment systems, so a homogenization pond is incorporated to provide flexibility and reliability to the general behavior of the future plant.

The civil works pond, with a storage capacity of 30 m3, also incorporates a stirring system by means of an agitator that guarantees the analytical equality of all the points inside the pond.

The biological reactor will be fed from the pond by submerged pumps.

Picture 2. Detail of the agitator inside the homogenization tank

Picture 2. Detail of the agitator inside the homogenization tank

Instrumentation and control

The plant is equipped with instrumentation and control elements that are centralized in an electrical panel, located inside a room.

The panel also includes a programmable logic controller and a touch screen for the operation and configuration of the plant. J. Huesa’s Instrumentation and Control team has designed the control panel so that it can be integrated in the client’s SCADA system, allowing a customized programming of all the operating parameters, as well as external connections of levels, alarms, pretreatment, among others, through different I/O modules.